- OUR MISSION

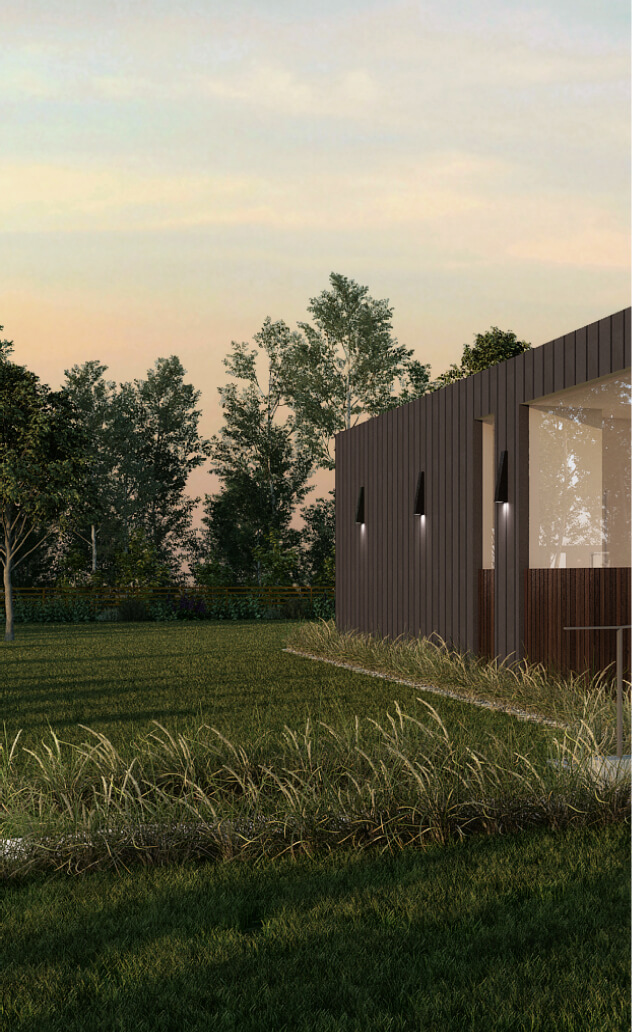

Leverage the efficiency of the 21st-century assembly

line to create sustainable, modular homes to help America’s housing crisis

Discover how our process works and why we need this innovation now

Leverage the efficiency of the 21st-century assembly

line to create sustainable, modular homes to help America’s housing crisis

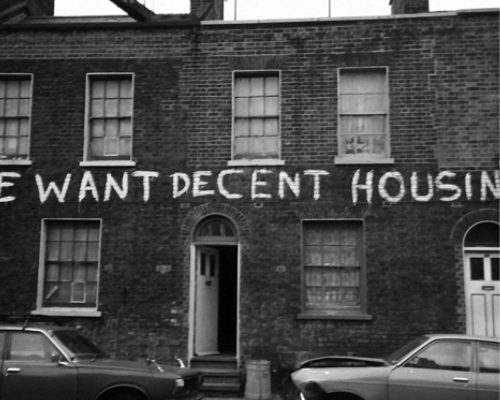

The U.S. rental and housing market has seen widespread cost increases over the past decade. Supply skepticism and shortage denialism are pushing against the actual solution to the housing crisis; building enough homes. Communities need a toolbox of housing solutions to support individuals of all income levels. We have designed multiple product lines that achieve this vision. Our housing is built to serve working families that are between true affordable housing and luxury housing.

In 1947, hundreds of thousands of GIs were returning from World War II and the U.S. needed to react by being new homes for these young veterans. The development firm, Levitt & Sons, headed by Abraham Levitt and his two sons, William and Alfred, built four planned communities called “Levittown”, that included stick-built, mass-planned suburban neighborhoods.

For the last century, our home-building process has remained the same. Typical developments require monthlong architecture feasibility studies and draftsman fees that can all balloon into six-figure charges.

Individuals face the challenge of making numerous design choices only to discover that their dream development is beyond their budget. This emphasizes the importance of managing budget constraints and making informed design decisions.

Supply chain issues and labor shortages can have a significant negative impact on the timeline and cost estimates of a construction project. This highlights the challenges and risks associated with these factors in the home-building industry.

The home-building process has remained unchanged for the last century, indicating that it is outdated and in need of improvement.

The RSL Homes process leverages shovel-ready plans for turnkey homes. After being presented with a potential project site, our team will send your organization a diagrammatic site plan, estimated development costs, and the expected development timeline. Our modular manufacturing process allows us to provide agreed-upon delivery times and fixed-firm pricing in our builds. By bringing home construction on an assembly line, the typical project can have open doors four to six months after zoning and planning approval. Our housing is built to serve working families that are between true affordable housing and luxury housing.

Copyright © 2024 RSL Homes. All rights reserved.